SAFE AND EFFECTIVE RUST REMOVAL FOR STAINLESS STEEL IN CLEANROOMS

Introducing the Sahara® Rust Removal Remediation Kit

Many cleanroom environments rely on stainless steel furniture and equipment due to its hygienic benefits, durability, and ability to support effective contamination control. However, even in controlled environments, rust can still develop on stainless steel. Even in cleanrooms, frequent cleaning, disinfectants, moisture, and temperature changes can compromise protective layers, increasing the risk of rust formation.

Left untreated, rust and rouge can:

- Introduce contamination risks into pharmaceutical manufacturing processes

- Compromise the integrity of stainless steel surfaces

- Lead to costly equipment downtime or premature replacement.

Our team at Cleanroom Supplies has produced this article introducing the Sahara® Remediation Rust Removal Kit, a product which will soon be available via the Cleanroom Supplies website. The article also explores how this solution compares with traditional rust removal methods in cleanroom environments.

The Challenges of Traditional Rust Removal

Stainless steel relies on a thin passive chromium oxide layer for corrosion resistance. Repeated use of aggressive cleaning agents – especially those containing chlorides or acidic solutions – can damage this passive layer, leaving stainless steel vulnerable to rust and corrosion.

Rust and rouge are not common issues within a cleanroom; however, when they do occur, appropriate precaution must be taken. Many traditional methods of removal are unsuitable for cleanroom environments.

Some of these processes include:

- Mechanical abrasion – this creates immediate visual results, however this method can generate particles and metal debris, risking further surface damage and cleanroom safety.

- Abrasive blasting – this is highly effective, but can produce significant airborne particles which can be risky in a cleanroom environment.

- Chemical removers – effective for removing rust, but can also impact the integrity of stainless steel surfaces.

- Pickling and passivation – often requires off-site processing and involves hazardous chemicals.

- Solvent cleaning and wiping – has limited effect on established rust, and may spread contamination rather than removing it.

The Solution

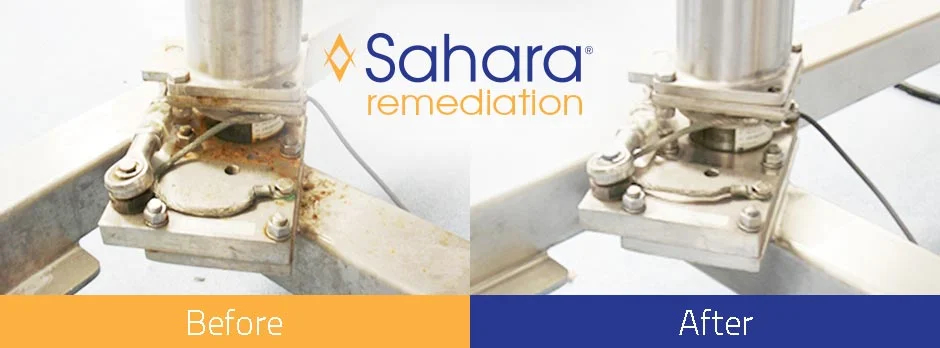

Images: Sahara® Remediation Kit. Credit: Foamtec

Foamtec’s Sahara® Remediation Rust Removal Kit is a chemical-free rust remediation process. This kit is specifically designed to address rust and rust-related contamination in cleanroom and controlled environments, where traditional methods may be unsuitable.

The Sahara® Remediation system uses a contained, targeted application process that isolates the affected area. This prevents the spread of particles, residues, or contaminants into the surrounding environment. The process is formulated to selectively react with iron oxide without attacking the underlying stainless steel. This allows effective rust removal whilst preserving the surface integrity and finish.

Key Benefits

- No abrasive action or particle generation

- Controlled, localised treatment

- Compatible with stainless steel surfaces

- Supports cleanroom integrity and compliance

- Reduces operational disruption.

- Requires no specialist equipment, and can be used by in-house cleanroom maintenance teams.

This kit includes the following:

- Sahara Sponge – A high-performance foam sponge engineered to loosen hardened disinfectant residues and rust particles without shedding.

- UltraSOLV® Sponge – A durable, cleanroom-grade sponge designed for aggressive cleaning of stubborn rust and rouge.

- UltraSOLV® Diamond ScrubPADS – Cleanroom-compatible abrasive pads that polish stainless steel to a 5-10 Ra surface finish, promoting self-passivation and preventing further corrosion.

- MiraWIPE® Microfibre Wipes – Ultra-fine microfibre wipes for final cleaning, effectively capturing residual particles and leaving surfaces residue-free.

Complete with a step-by-step- instructional guide and validation documents.

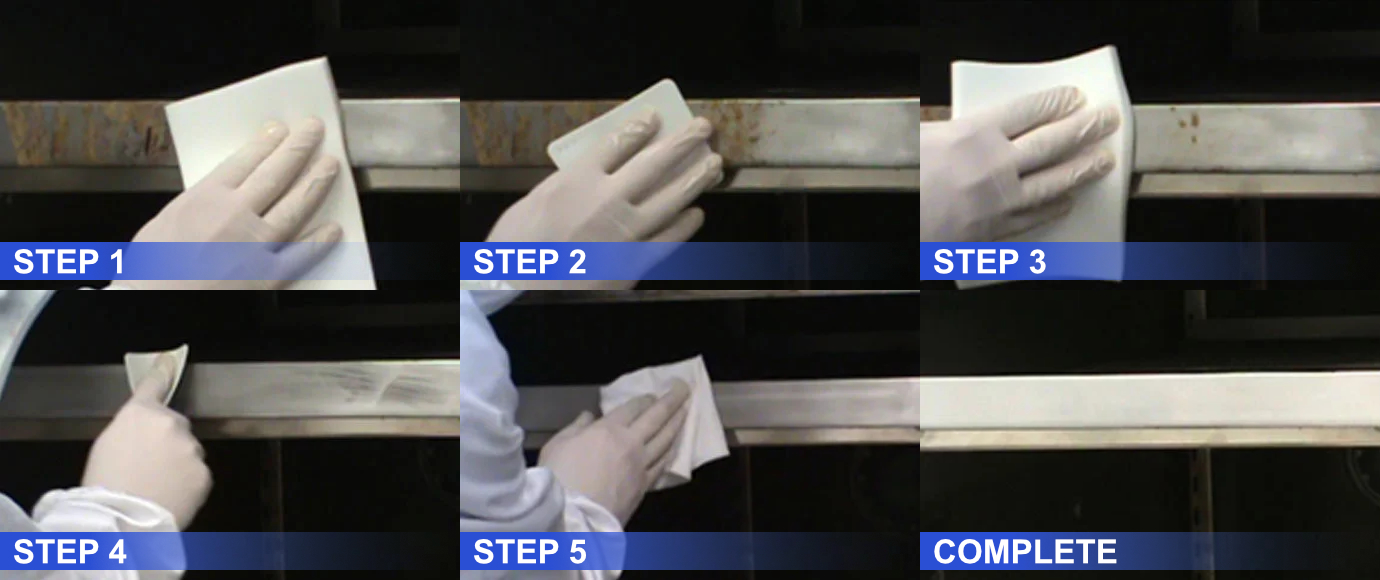

Images: Sahara® Remediation Kit. Credit: Foamtec

Step-by-Step Rust Removal with Sahara® Remediation Kit

- Identify the area and pre-clean the surface with an UltraSOLV® Sponge, wetted with DI Water to reduce the risk of further corrosion.

- Scrub the surface free of heavy corrosion with UltraSOLV® 280D ScrubPAD.

- Clean the surface prior to the final polish with the UltraSOLV® Sponge, wetted with DI Water.

- Polish the surface with the UltraSOLV® 1350D ScrubPAD.

- In order to remove any debris left over from polishing, clean the surface with MiraWIPE® Microfibre Wipes, wetted with 70% IPA. IPA is extremely effective for use on stainless steel, as it evaporates quickly and leaves no residue. View our stainless steel care guide for more information.

Images: Sahara® Remediation Kit. Credit: Foamtec

Availability

The Sahara® Remediation Rust Removal Kit will soon be available on the Cleanroom Supplies website. For updates, follow us on social media or contact our team with any questions.

Email: [email protected]

Tel: 01768 896 800

You may also be interested in…

Cleanroom Stainless Steel Cleaning Advice and Tips

3 Huge Benefits of Electropolished Stainless Steel Furniture

Customised Stainless Steel Furniture and Bespoke Fittings