3 HUGE BENEFITS OF ELECTROPOLISHED STAINLESS STEEL FURNITURE

November 11, 2022 | Cleanroom Supplies Blogger

What is Electropolishing?

It is an electrochemical finishing process, often applied to 300 series stainless steel. For example 304 and 316 grade.

It works by removing a thin layer of the metallic material from the workpiece, in order to obtain a smoother metal surface, whilst also stripping away surface oxides and impurities. As the roughness of the surface is decreased, the resistance against bacterial growth is increased. For these reasons, electropolishing has found vast engineering applications in many pharmaceutical and GMP cleanrooms.

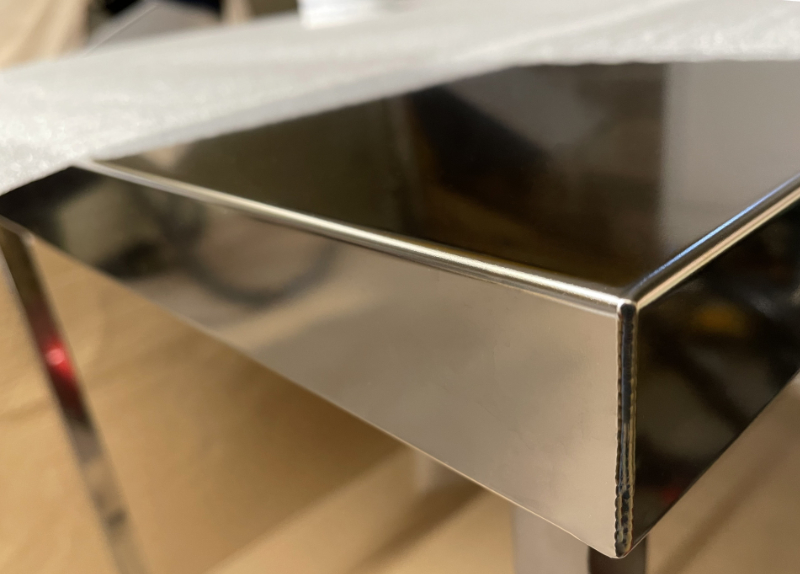

The most noticeable benefit of the process is the resulting of a bright, smooth metal surface. However, the practical differences are far more beneficial, leaving the material hygienically pure and highly resistant to bacterial growth and corrosion.

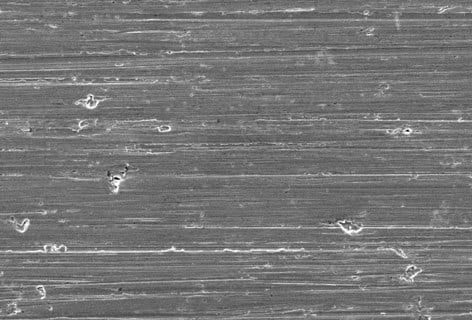

Standard DP1 brush finish Stainless Steel

Electropolished finish Stainless Steel

During mechanical processing, the metal surface comes with much contamination and is relatively coarse, as a result of rough machining in the steel mills. The coarse surface can lead to the adhesion of bacteria, which advances bacterial colonisation and biofilm development. Stainless steel in particular is susceptible to bacterial attachment, and it is the most frequently used material for construction of vessels, piping, valves and various types of cleanroom and laboratory furniture.

However, in cleanroom industries, the need for hygienic and contaminant free surface is desirable. For this reason, Electropolished Stainless Steel is a material highly suited to applications in medical, food, pharmaceutical, cleanroom and semiconductor cleanroom applications.

Mechanically Polished Stainless Steel Surface Finish

Electropolished Stainless Steel Surface Finish

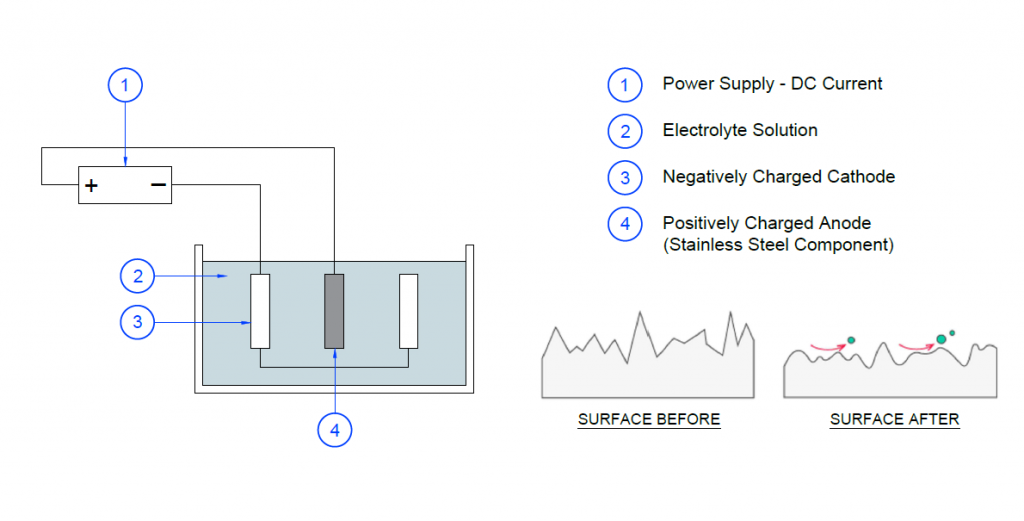

How Does Electropolishing Work?

Electropolishing Process Diagram

The stainless steel component, serving as a positively charged anode, is submerged along with the cathode in a temperature controlled bath of electrolyte. When a DC current is conducted from the anode to the cathode via the electrolyte, the current causes metal ions on the surface of the component to oxidise. Surface ions are removed from the surface of the component, resulting in a smoother finish – free from imperfections and microscopic impurities.

The electropolishing process is accompanied by oxygen evolution adjacent to the working electrode, which is useful and effective for the reduction of bacterial colonization over the surface. Moreover, hydrogen embrittlement is avoided and biofilm adhesion is reduced by elimination of roughness and micro burrs of the surface.

The finished result looks just as pictured – a smooth, shiny surface, free from impurities.

The physical aesthetic is not the only benefit, however.

The lack of microscopic pits, scratches, burrs and imperfections has hygienic benefits that make the material well-suited to higher grade cleanroom environments.

The Practical Benefits

Improved Sanitation Control for Pharmaceutical Applications.

Sanitation is a key concern for any product purposed for sterile applications. Electropolishing removes the biofilm formed on 304 and 316 grade stainless steel, thus protecting against bacterial colonisation. Additionally, by having a smoother metal surface and the elimination of microscopic pits and impurities, this means that the treatment effectively provides a ‘non-stick’ surface, so that contaminant build-up can be wiped away at ease.

This means that disinfection is improved, more effective and longer lasting.

For more information about the cleaning, care and maintenance of stainless steel in general, we recommend reading the following two articles:

Passivation, Pickling, Polishing & Cleaning

Cleaning Methods for Stainless Steel

Improved Structural Integrity

As a non-mechanical process, this means that no mechanical tools come into contact with the component, so there is no risk of creating any microscopic fissures on the surface. These can weaken the integrity of stainless steel – so by eliminating any structural weaknesses that contribute to fatigue points, a stronger, longer-lasting form is established.

Higher Resistance to Corrosion and Tarnishing

Mechanical cutting, machining, handling and polishing can leave iron and abrasive particles embedded within a material surface. These surface contaminants disrupt the formation of stainless steel’s naturally occurring oxide layer – the layer that resists against corrosive activity. Microscopic surface irregularities and burrs may conceal dangerous bacteria and embedded contamination, which in turn can cause rust or corrode under repeated tough chemical disinfection procedures.

On the contrast, electropolishing removes ingrained particles or pits that may lead to corrosion. Not only that, but it improves the surface chemistry of the material. The process dissolves corrosive iron particles from the surface, whilst also leaving it with a higher concentration of Chromium. The improved surface will form a thicker protective oxide layer. This allows for the component to be exposed to a variety of chemicals and harsh environments, without tarnishing or corroding.

Get In Touch

Here at Cleanroom Supplies, we fully understand the importance of good design and quality manufacture when dealing with controlled pharmaceutical environments.

Take a look at our Stainless Steel Cleanroom Furniture category on our website, or why not consider our Bespoke Hygienic Furniture Design Service.

Do you require specialist finishes on your bespoke stainless steel items? Or perhaps you simply require cleanroom-suitable furniture designed for your industry. Please get in touch with our experienced team to discuss your requirements – we would be delighted to assist you and provide a FREE Design Service!

You may also be interested in our hygienic furniture catalogue. Click here to download